Image 1 of 5

Image 1 of 5

Image 2 of 5

Image 2 of 5

Image 3 of 5

Image 3 of 5

Image 4 of 5

Image 4 of 5

Image 5 of 5

Image 5 of 5

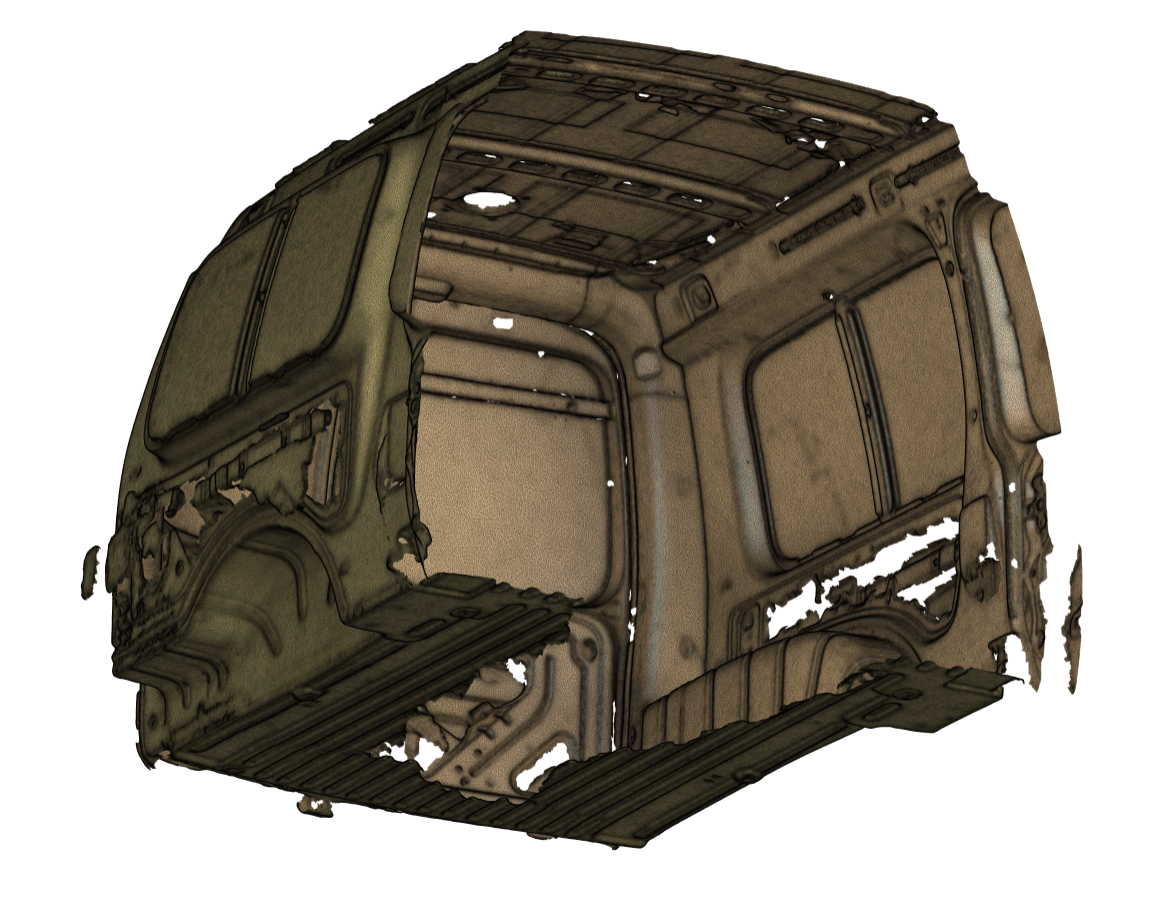

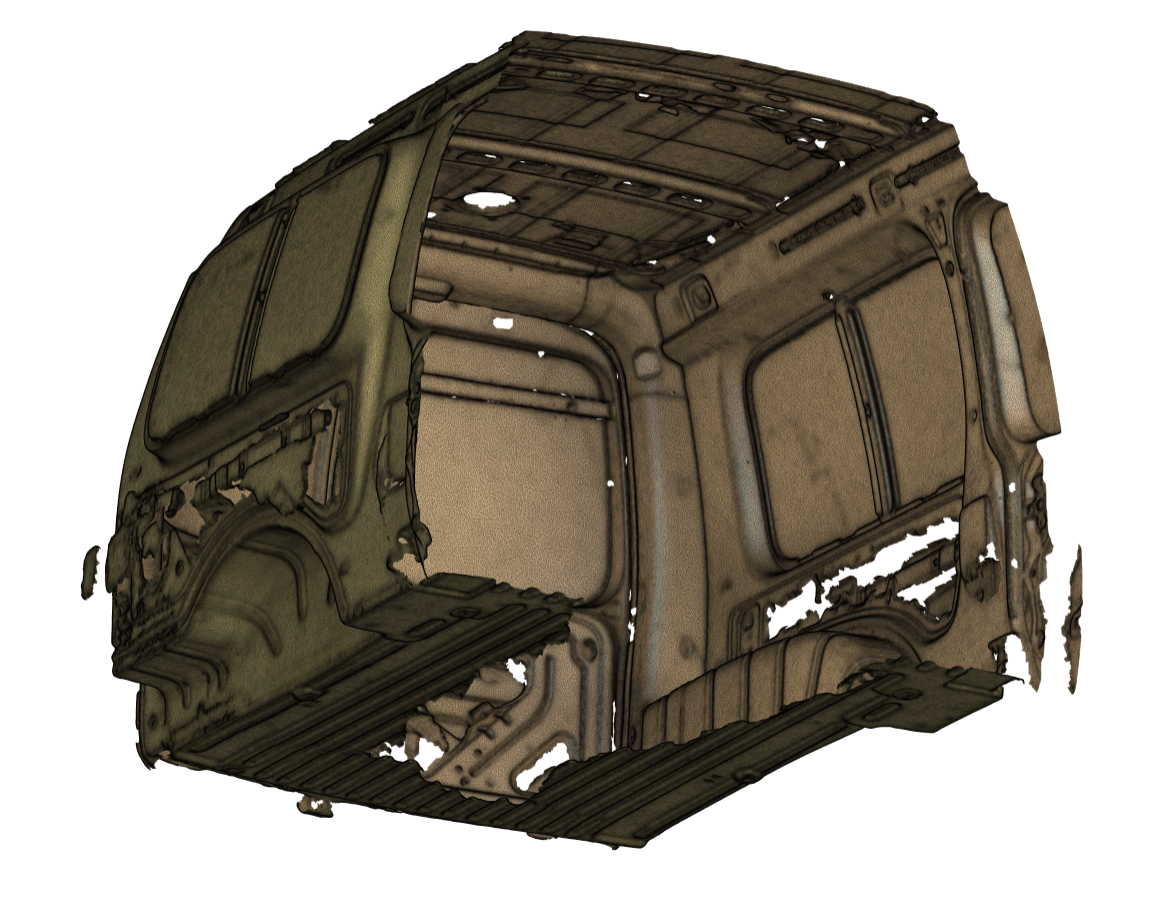

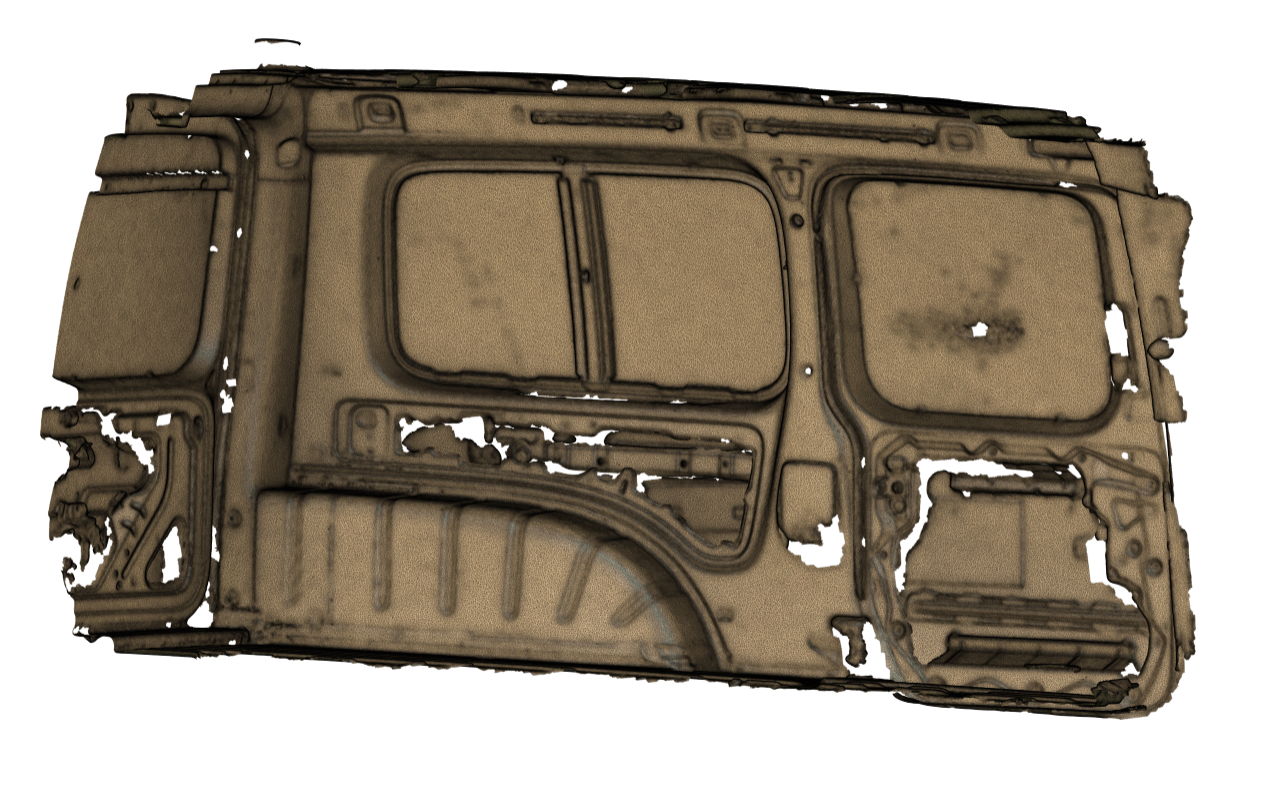

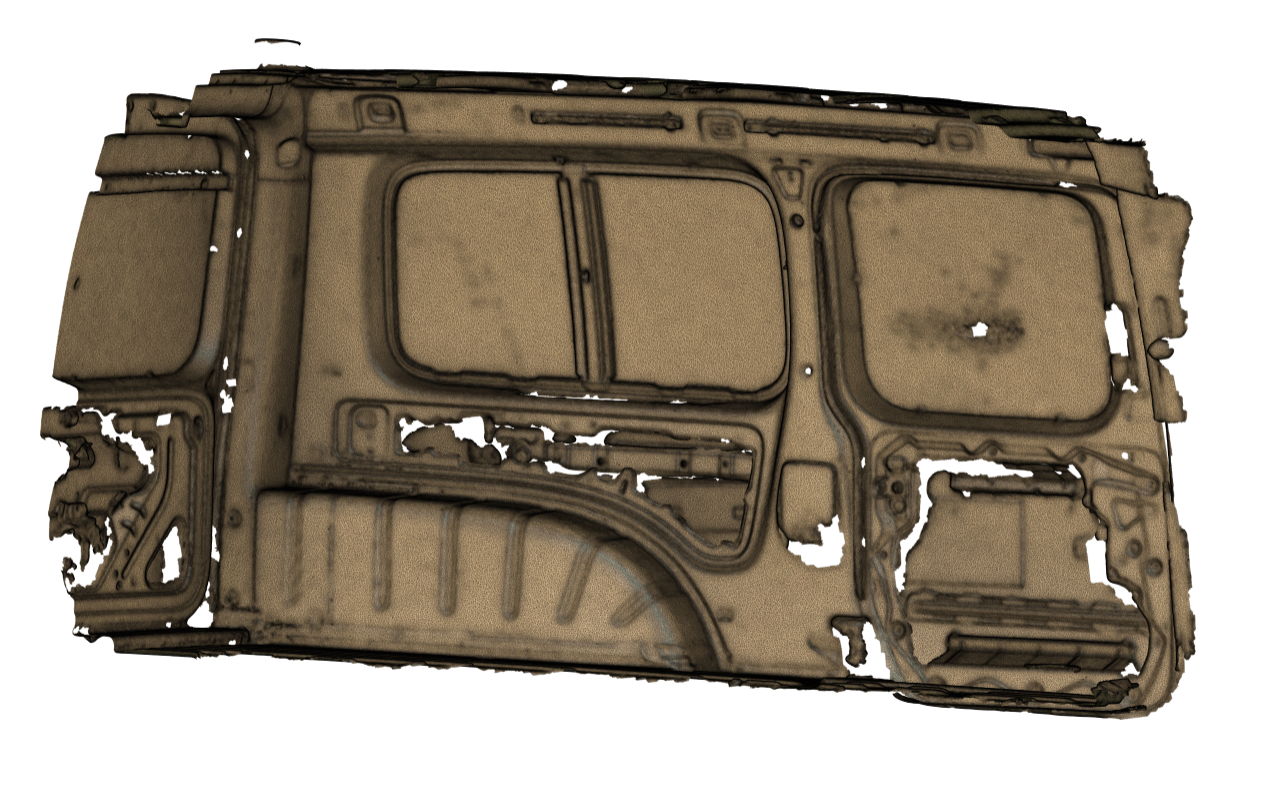

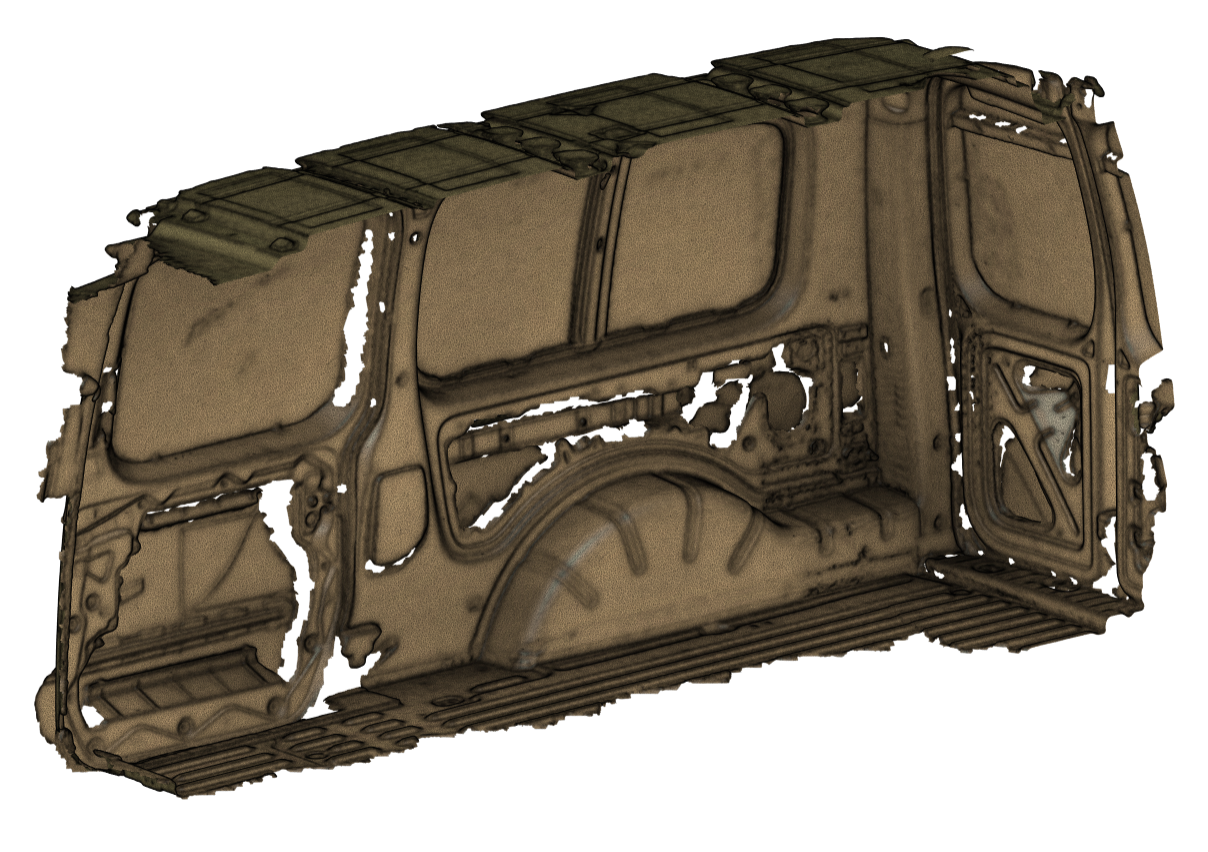

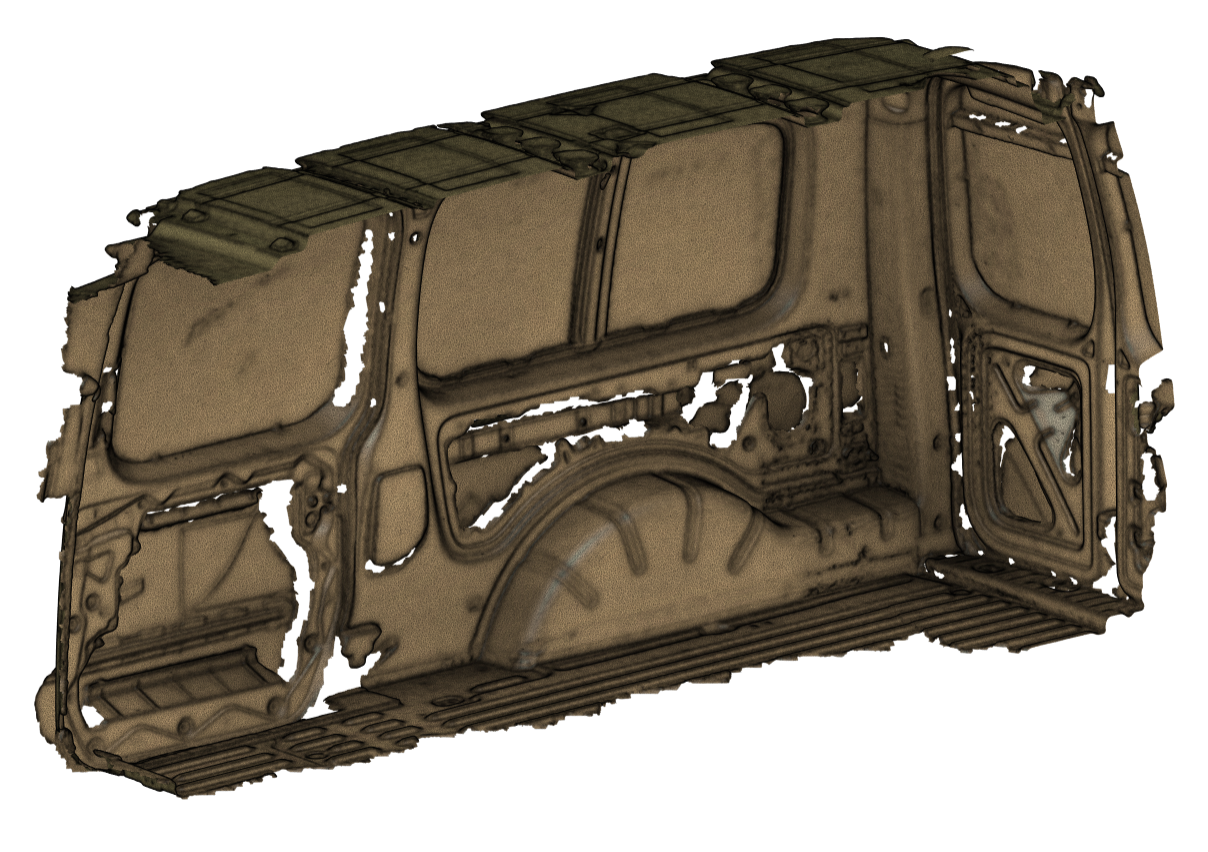

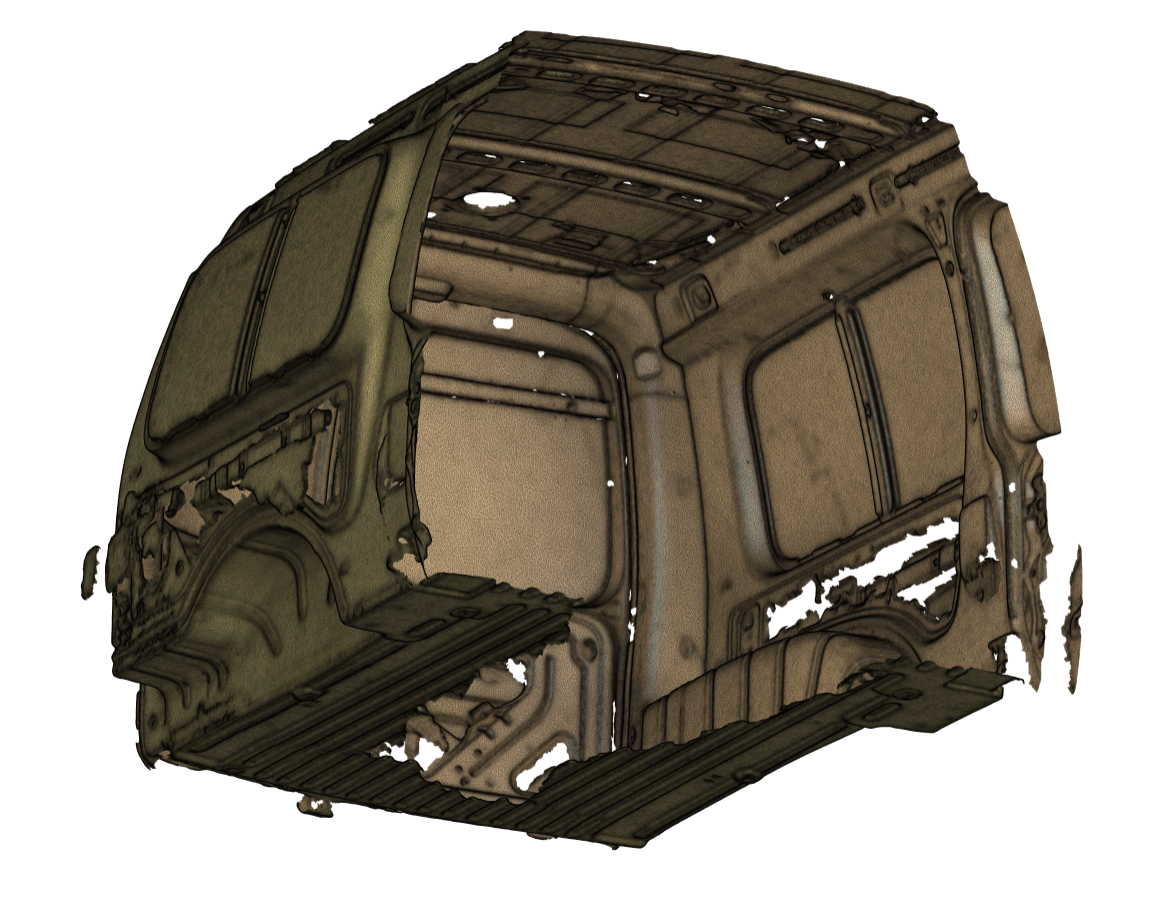

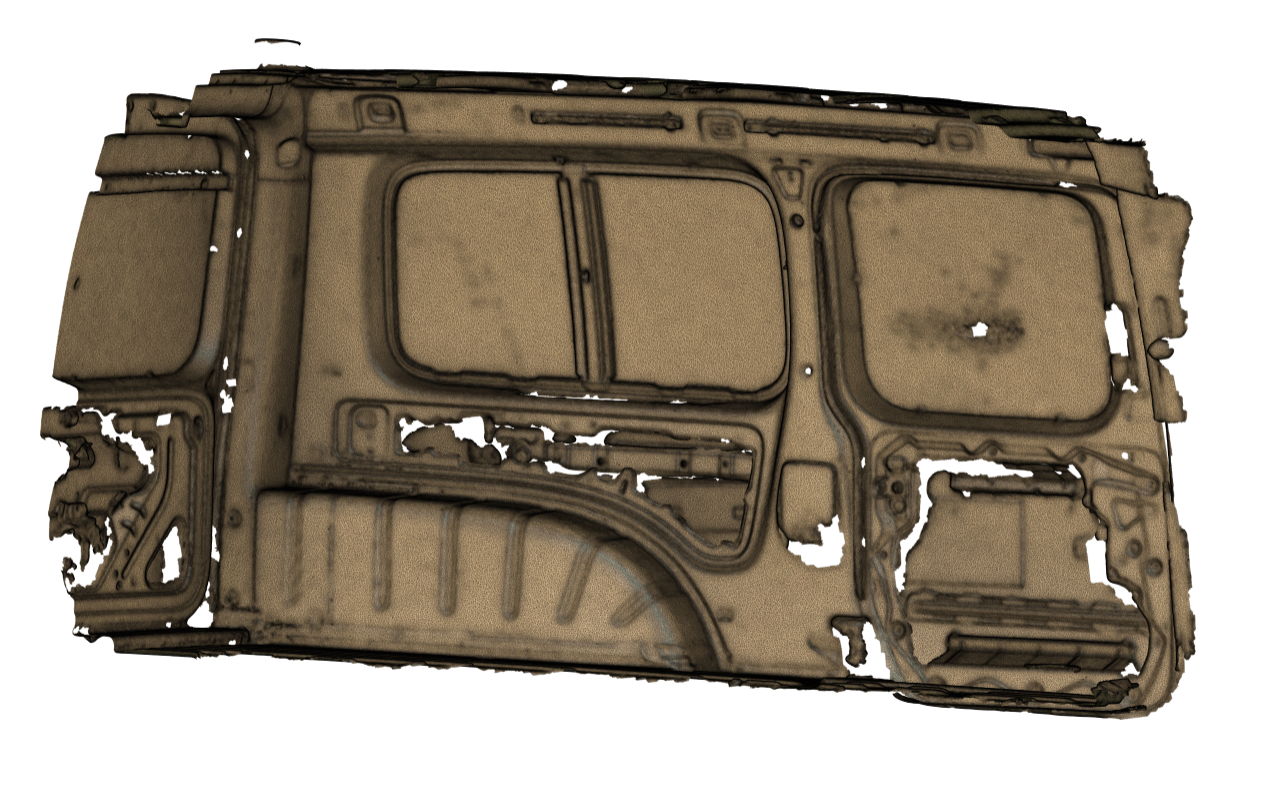

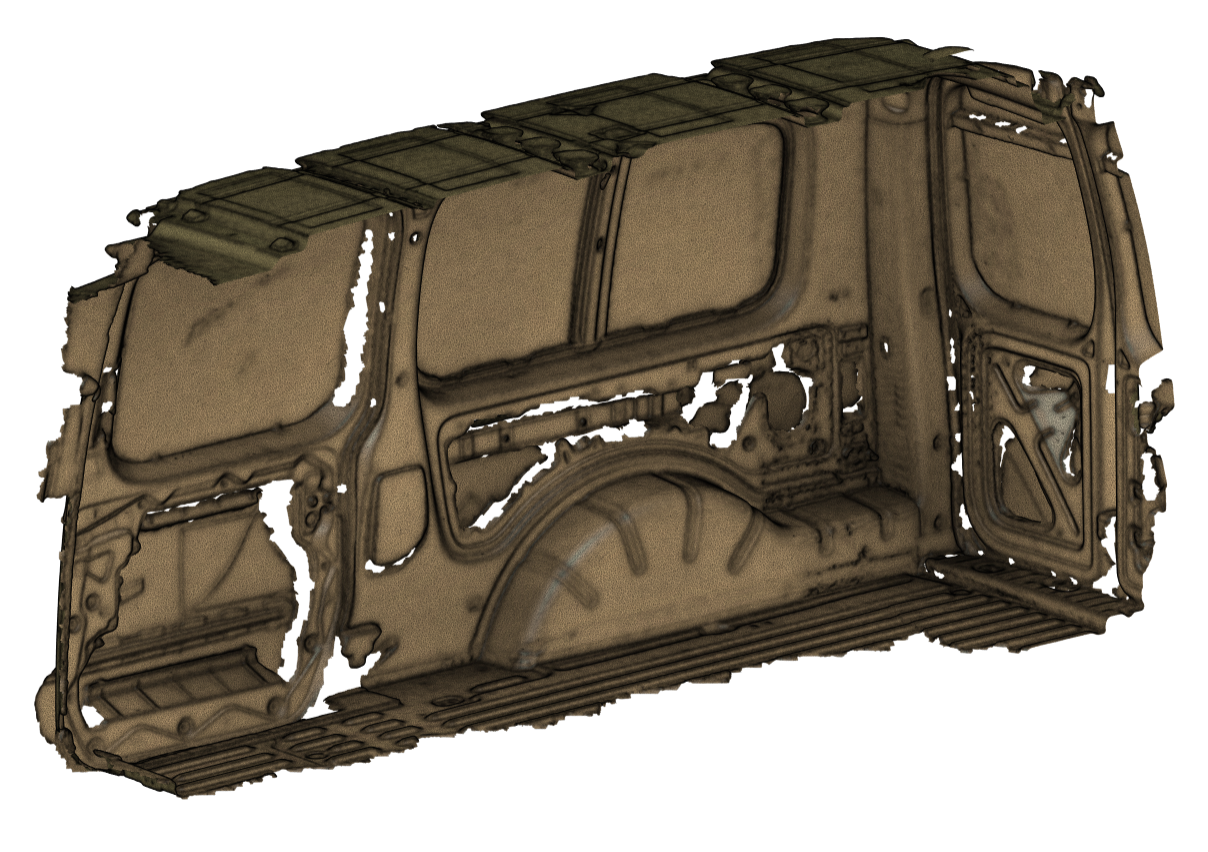

Volkswagen Caddy MK4 Maxi LWB 3D Scan Data

Comprehensive 3D scan data of the VW Caddy MK4 LWB Cargo area. This perfect one-to-one scanned model provides the ideal foundation for designing bespoke and well fitted parts into the back of the van. This model is perfect for laying out items, assessing space, and bespoke design of precisely fitted features such as cabinets, shelving or other useful racking. Space is without a doubt at a premium in these vans, so being able to confidently use all of it is a gamechanger.

Produce near perfect fitting parts first time

Reduce re-work

Utilise 100% of the available space

Ability to view designs in a perfect scale environment prior to manufacture

A 3D scan of this size and complexity will require a good laptop or tower PC to work effectively. I personally run this smoothly on my gaming laptop which is Ryzen 7, 32Gb of RAM and has a 6Gb graphics card. I cannot guarantee smooth functionality with lower specification equipment.

What you will receive

A Fusion 360 export (.F3Z) file containing the imported mesh which has been pre aligned to the work coordinate system. This is ready to use immediately for design within Fusion 360 (which is free using a hobbyist licence). The data can also be exported from Fusion into the vast majority of other high performance CAD packages such as SolidWorks.

NOTE

The file is large and make take some time to download depending on WiFi speed.

Due to the complexity and size of the mesh, a good laptop/CAD workstation will be required to run this effectively.

Due to the file size, the download from the website itself will not contain the scan data. The download will contain the link to the files which will be accessed through google drive.

The link and downloaded content is not for further distribution post purchase.

DISCLAIMER

The data within this 3D scan has been checked and verified to be authentic to the van that the scan was taken from. However, scans should be used as a reference for design which is verified by actual measurements taken by the designer themselves. I cannot guarantee that this scan will be 100% representative of your, or your customer’s vehicle due to inaccuracies in the scan, and variance of individual vehicles themselves.

Automotive tolerances for body panelling can be as great as +-5mm depending on make and model. This should be taken into consideration when using this scan data to design componentry for other vehicles.

The images depict the actual scan data within Fusion 360. The key data is all present but you will notice that cavities within panelling or joins with matte black components are lacking and or completely devoid of data.

A 3D scan of this size and complexity will require a good laptop or tower PC to work effectively. I personally run this smoothly on my gaming laptop which is Ryzen 7, 32Gb of RAM and has a 6Gb graphics card. I cannot guarantee smooth functionality with lower specification equipment. The mesh can be simplified further within Fusion to reduce load on the processor, but this will come at a cost in terms of resolution.

Comprehensive 3D scan data of the VW Caddy MK4 LWB Cargo area. This perfect one-to-one scanned model provides the ideal foundation for designing bespoke and well fitted parts into the back of the van. This model is perfect for laying out items, assessing space, and bespoke design of precisely fitted features such as cabinets, shelving or other useful racking. Space is without a doubt at a premium in these vans, so being able to confidently use all of it is a gamechanger.

Produce near perfect fitting parts first time

Reduce re-work

Utilise 100% of the available space

Ability to view designs in a perfect scale environment prior to manufacture

A 3D scan of this size and complexity will require a good laptop or tower PC to work effectively. I personally run this smoothly on my gaming laptop which is Ryzen 7, 32Gb of RAM and has a 6Gb graphics card. I cannot guarantee smooth functionality with lower specification equipment.

What you will receive

A Fusion 360 export (.F3Z) file containing the imported mesh which has been pre aligned to the work coordinate system. This is ready to use immediately for design within Fusion 360 (which is free using a hobbyist licence). The data can also be exported from Fusion into the vast majority of other high performance CAD packages such as SolidWorks.

NOTE

The file is large and make take some time to download depending on WiFi speed.

Due to the complexity and size of the mesh, a good laptop/CAD workstation will be required to run this effectively.

Due to the file size, the download from the website itself will not contain the scan data. The download will contain the link to the files which will be accessed through google drive.

The link and downloaded content is not for further distribution post purchase.

DISCLAIMER

The data within this 3D scan has been checked and verified to be authentic to the van that the scan was taken from. However, scans should be used as a reference for design which is verified by actual measurements taken by the designer themselves. I cannot guarantee that this scan will be 100% representative of your, or your customer’s vehicle due to inaccuracies in the scan, and variance of individual vehicles themselves.

Automotive tolerances for body panelling can be as great as +-5mm depending on make and model. This should be taken into consideration when using this scan data to design componentry for other vehicles.

The images depict the actual scan data within Fusion 360. The key data is all present but you will notice that cavities within panelling or joins with matte black components are lacking and or completely devoid of data.

A 3D scan of this size and complexity will require a good laptop or tower PC to work effectively. I personally run this smoothly on my gaming laptop which is Ryzen 7, 32Gb of RAM and has a 6Gb graphics card. I cannot guarantee smooth functionality with lower specification equipment. The mesh can be simplified further within Fusion to reduce load on the processor, but this will come at a cost in terms of resolution.